Empowering Smart Manufacturing with Intelligent Line Monitoring

Transform your manufacturing with Maisvch industry 4.0 communication solutions. Real-time monitoring, predictive analytics, and seamless automation integration

The Intelligent Manufacturing System (IMS) plays a key role in realizing Industry 4.0 by transforming traditional production lines into smart, automated environments. These comprehensive manufacturing solutions integrate cutting-edge technologies including artificial intelligence, Industrial Internet of Things (IIoT), big data analytics, and edge computing to achieve unprecedented levels of automation and intelligence in production processes.

Intelligent Manufacturing Systems fundamentally transform traditional production environments by creating interconnected, data-driven ecosystems that enable:

Advanced analytics process vast amounts of production data instantaneously, providing actionable insights for immediate optimization

AI-powered algorithms anticipate equipment failures before they occur, minimizing downtime and reducing maintenance costs

Continuous monitoring and automated quality control ensure consistent product excellence throughout the production cycle

Dynamic allocation of materials, energy, and human resources based on real-time demand and production requirements

Seamless connectivity between suppliers, manufacturers, and customers for enhanced visibility and coordination

Modern intelligent manufacturing environments demand robust, scalable, and reliable communication infrastructure.

Robots and machines must deliver real-time data on operational parameters. This information needs to be collected by the production line control system and uploaded to upstream systems for continuous monitoring and analysis.

The system must facilitate the smooth transmission of commands from the upstream system to the production line. This is done via wired or wireless communication using industrial switches or IoT devices, ensuring timely instruction delivery.

The production environment typically involves a wide variety of terminal devices. Therefore, the system must accommodate different connection types, such as serial ports, Ethernet ports, and others.

The system should be capable of monitoring the operation of the production line, sending alerts in case of material shortages or anomalies, and overseeing the functioning of production equipment to prevent disruptions.

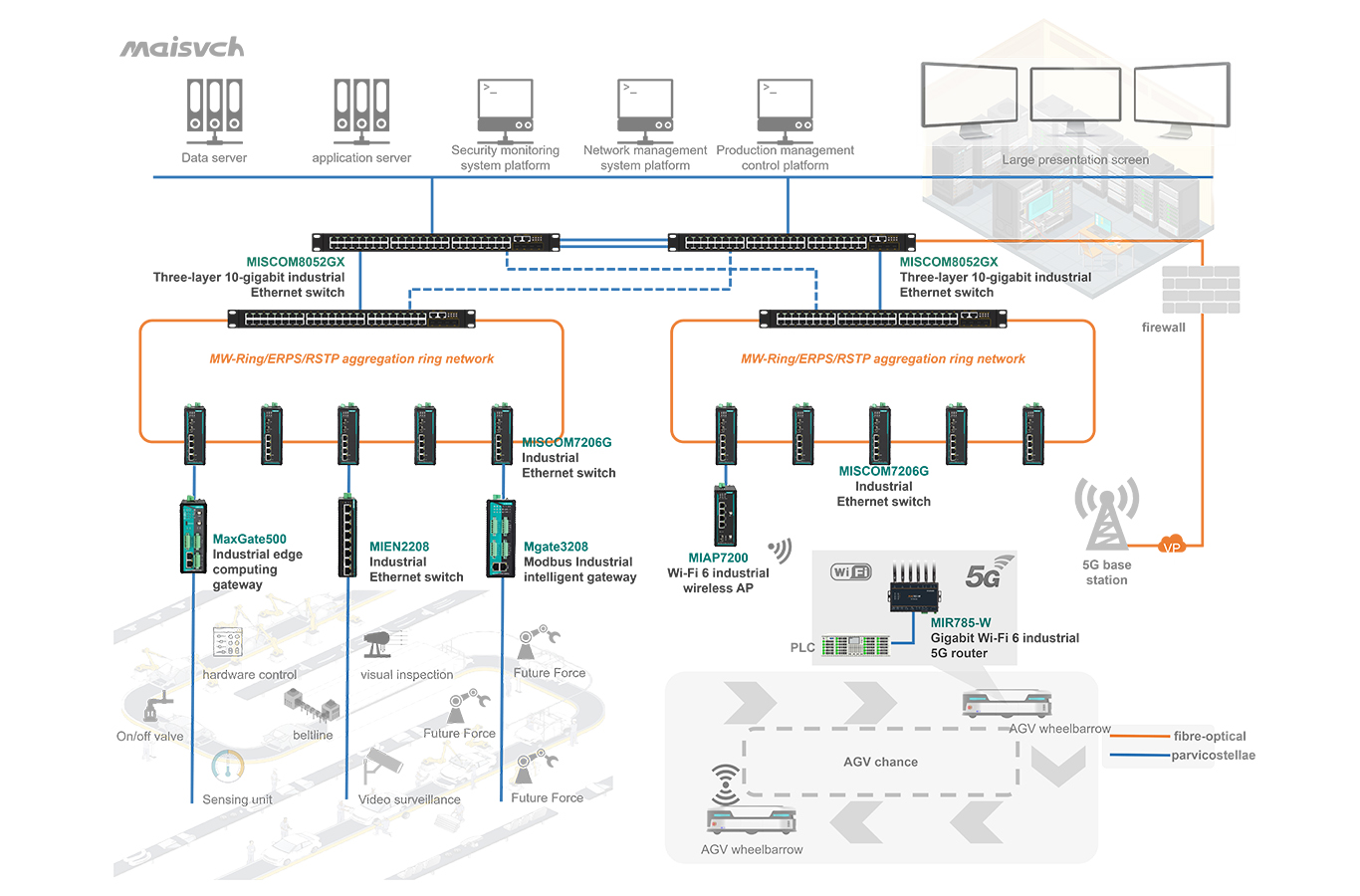

Maisvch offers comprehensive solutions tailored to meet the specific requirements of intelligent manufacturing systems. The approach is divided into two main components: Smart Production Line Monitoring and Control and Automated Guided Vehicle (AGV) Operations.

Our solution utilizes Industrial Edge Computing Gateways to standardize communication protocols across different production line devices, simplifying management and monitoring. We deploy MIEN2208 industrial Ethernet switches and Modbus industrial smart gateways to enable seamless integration of devices operating on different bus systems. This facilitates smoother interactions between machines and optimizes the overall workflow.

For automating material handling and transport, Maisvch offers a robust wireless solution with MIR785-W routers and MIAP7200 wireless access points. This infrastructure allows real-time data transmission to the central management platform, enabling automated instruction execution for AGVs. The system enhances operational efficiency by ensuring the seamless automation of both production and material transport processes.

This diagram highlights how Maisvch products, from industrial Ethernet switches to edge computing gateways and wireless access points, create an interconnected network that fosters smooth communication between devices and centralized systems. This ensures an optimized, automated production process.

Maisvch stands out as the preferred choice for intelligent manufacturing solutions due to the following advantages:

With 24 years of experience in industrial communication, we understand the complexities and demands of manufacturing automation.

Maisvch offers a complete ecosystem of industrial communication products, ensuring seamless integration, simplified procurement, and unified technical support across your entire network infrastructure.

Our products are designed for effortless integration into existing production lines, minimizing disruptions during implementation.

By leveraging the latest technologies, we offer solutions that boost productivity, improve product quality, and reduce operational costs.

Maisvch’s solutions are designed to grow with your business, making them suitable for both small-scale and large-scale manufacturing environments.

From consultation to post-implementation assistance, Maisvch provides 5-year warranty, unmatched customer support, ensuring the smooth operation of your intelligent manufacturing system.

Maisvch ensures compliance with rigorous industry standards to guarantee product performance and reliability:

Are you ready to optimize your production line with Maisvch’s intelligent manufacturing solutions? Contact us today to explore how our cutting-edge technologies can help automate your processes, improve efficiency, and deliver superior quality. Our expert team is ready to guide you through the implementation process.